Research & Innovation

Link copied!

The link has been copied to the clipboard

Over the past decades, DFRL has continuously advanced its high-quality refractory materials production

through sustained research and development, establishing itself as a leader in the industry and

preserving a rich tradition and history. Building on our core business in refractory materials, we are

leveraging our accumulated expertise in technology research to explore new avenues for growth.

In the full cement manufacturing and application process, “real-time control” is critical. Our R&D

center is equipped with various testing and evaluation tools that measure the fundamental properties of

cement and simulate a wide range of real-world conditions in laboratory settings.

We also employ computer simulation and laboratory analysis equipment—including thermal stress analysis,

fluid analysis, laser particle analysis, and X-ray diffraction—to improve prediction accuracy and

optimize our R&D capabilities. This approach not only ensures stable product quality but also drives

continuous innovation and advancement in refractory materials technology.

Optimize products to better meet customer

needs

Our primary goal is to “enhance

customer satisfaction.”

In addition to researching the essential characteristics of our products, we place a strong focus on

“researching customer value enhancement”—that is, studying how well our products meet customer

expectations and deliver high value.

Before delivering products to our customers, we conduct continuous evaluations throughout the

manufacturing process, including hourly, daily, and monthly inspections.

We then collect customer feedback on the products and carry out cyclical research and improvements in

our laboratories.

By producing high-quality products that satisfy customers, we are committed to enhancing their work

efficiency.

Collaborative Research and Development for Enhanced Product Innovation at

DFRL

At DFRL, we develop specialized technical teams for every product group.

Additionally, we are currently organized into the R&D Center and the Testing Center to facilitate knowledge sharing across each group and link it with the development of new technologies and products. We categorize our technical personnel into two main groups and conduct collaborative research for each product group to jointly explore various topics. By enabling our researchers to exchange knowledge and technical expertise across departments, we are able to further enhance product development that increases customer value.

Additionally, we are currently organized into the R&D Center and the Testing Center to facilitate knowledge sharing across each group and link it with the development of new technologies and products. We categorize our technical personnel into two main groups and conduct collaborative research for each product group to jointly explore various topics. By enabling our researchers to exchange knowledge and technical expertise across departments, we are able to further enhance product development that increases customer value.

Product Tracking and Inspection (Testing Center)

Short-term, Medium-term, and Long-term Technical Planning, as well as the iteration of new and existing products (R&D Center)

Enhancing Product Stability and Technology with

Advanced Analytical Equipment

at DFRL

DFRL is equipped with various advanced technologies, including XRF, XRD, electron microscopy, energy

spectroscopy, and more. By employing full-spectrum fitting for precise quantitative analysis (Rietveld

method), we are able to achieve real-time control and accurate quantification of the chemical

composition and mineral phases of our products. The entire process of fine product inspection is managed

through digitalization and standardized management, improving product stability and technological

content.

X-Ray Diffractometer

X-Ray Diffractometer X-Ray Fluorescence Spectrometer

X-Ray Fluorescence Spectrometer

Scanning Electron Microscope

Scanning Electron Microscope

High-Temperature Performance

Laboratory

High-Temperature Performance

Laboratory High-Temperature Expansion Meter,

Refractoriness Tester, Melting Point and Melting Speed Tester

High-Temperature Expansion Meter,

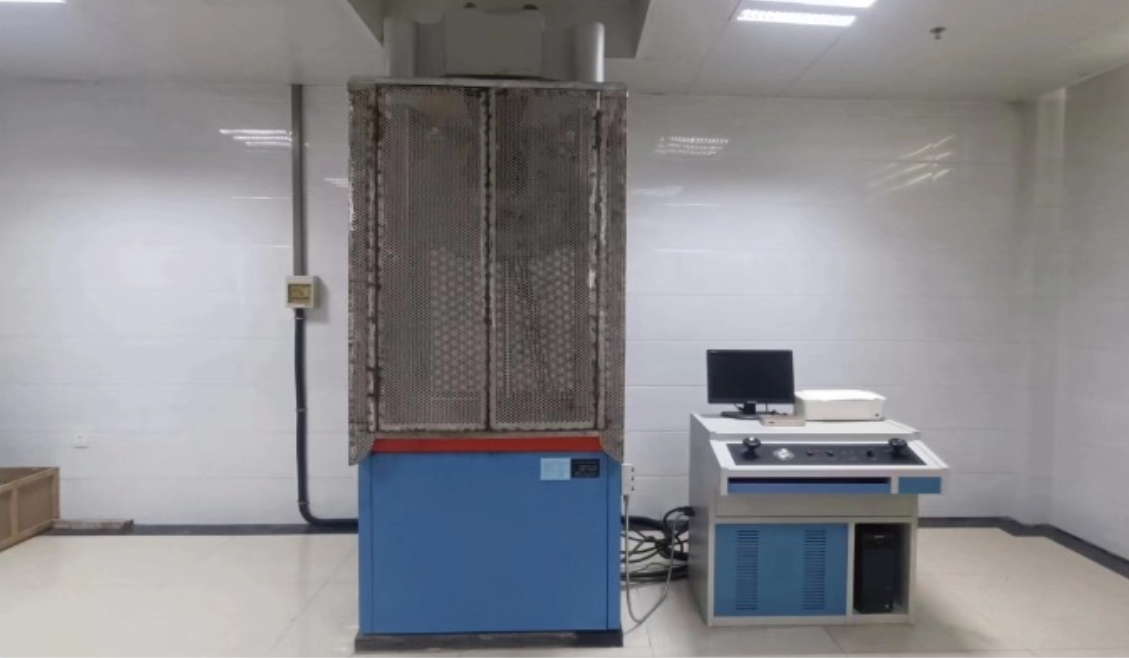

Refractoriness Tester, Melting Point and Melting Speed Tester  200-Ton Universal Testing

Machine

200-Ton Universal Testing

MachineMessage from the R&D Center/Testing Center

In an ancient village, a young potter was troubled by the recurring damage to his high-temperature

kiln, which prevented him from improving the quality of his pottery. One night, he dreamed of a

fire phoenix, which used indestructible feathers to build a kiln capable of withstanding intense

heat. The fire phoenix told him that these feathers were made from the essence of the earth and

the power of the stars.

Upon waking, the potter was determined to find this magical material. After much hardship, he

discovered a shining stone in a mysterious mountain, which he successfully used to make

heat-resistant bricks and construct a new kiln. The quality of the village pottery improved

dramatically. He shared this discovery with craftsmen from distant lands, thus advancing the

development of refractory materials.

This is the story of refractory materials—an epic of dreams, exploration, and wisdom. As a

cornerstone of modern industry, the importance of refractory materials is undeniable. Whether in

traditional industries or emerging fields, refractory materials silently play a crucial role. With

continuous technological innovation and development, refractory materials will continue to

contribute to industrial progress and the advancement of human society.

Choosing high-quality refractory materials means choosing an efficient, safe, and sustainable

future. Through relentless innovation and effort, humankind has not only realized the legend of

the fire phoenix but has also laid a solid foundation for the development of modern civilization.

No matter how technology progresses in the future, refractory materials will continue to shine

like the fire phoenix in the high-temperature furnaces of industry.